The coil spring is the necessary carrier for connecting the upper control and the body. A high-quality five-core spring wire must have good flexibility and elasticity. The overall spiral structure can resist various electromagnetic interferences and effectively suppress high-frequency interference. The following is a description of the latest generation of coil spring wire from Kuanhui Technology.

Outer Sheath Material: TPU

TPU is also known as thermoplastic polyurethane elastomer rubber, referred to as polyurethane.

The material is characterized by abrasion resistance, tear resistance, high tensile strength, high elongation, and low long-term compression set. Good weather resistance, resistance to high and low temperature (-40 ° C ~ 120 ° C), water resistance, mildew resistance, good resistance to corrosive oils and chemical solvents. The outer sheath is treated with a matte finish, which is less prone to yellowing and harder than a bright surface.

he outer sheath has a diameter of 7.5 mm.

Inner core sheath insulation: TPEE

TPEE is also known as thermoplastic polyester elastomer.

The material is characterized by a wide temperature range and can be used from -70 ° C to 200 ° C.

High bending modulus at high temperatures makes it suitable for high temperature parts. It has good flexibility at low temperature, excellent fatigue resistance, and low loss of Shield. It can be used in multiple cycles.

It has excellent chemical stability. Although it will degrade under the action of ultraviolet rays, it can be encapsulated in the outer skin, which can effectively block the direct irradiation of ultraviolet rays. Moreover, by adding ultraviolet protection additives during the production process, it can effectively solve the chemical reaction. reaction.

Inner five-core material: tinned copper wire.

Tinned copper wire is more conductive and stable than single copper wire, with stronger oxidation resistance and longer service life.

Each core has 42 tinned copper wires wound together for a total of 210 tinned copper wires. Each thin wire is not allowed to have a joint and must be a complete copper wire.

Single strand core wire is 0.5 square.

Mating connector material: waterproof connector and nut: US HEYCO

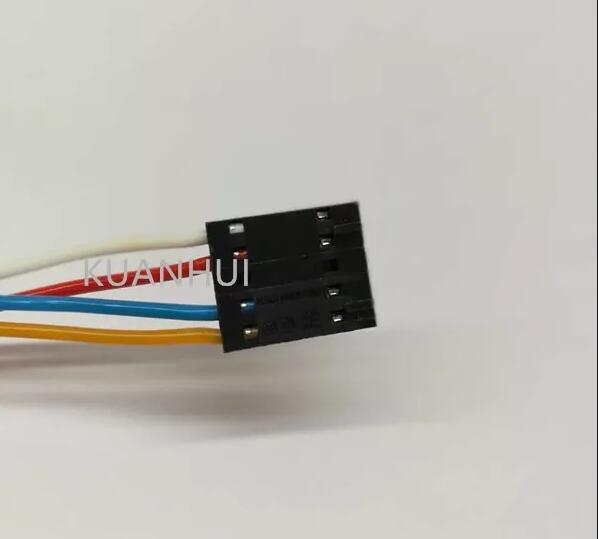

Connector: AMP connector of the American TE Group.

Body connector: DEUTSCH connector of the American TE Group.

SIBAS under the US TE Group.

Shenzhen Lingke electrical connector.

|